Altitude

Altitude (Vacuum) testing is used to determine whether items can withstand the low pressure environment associated with high altitude or use in aircraft. Altitude testing is important for products that are stored and/or operated at high ground elevations, transported or operated in unpressurized areas of aircraft, or exposed to a rapid decompression event. If the item is exposed to a rapid decompression, it is important to determine if it will damage the aircraft or present a hazard to personnel.

Altitude Test at DES

Delserro Engineering Solutions, Inc. (DES) has many years of experience performing altitude testing and can assist customers in setting up a test using the proper test conditions. So if you do not know what test conditions that you should use, or what specification to choose then we will help you because we are altitude testing experts!

Some common altitude testing specifications:

- IEC 60068-2-13, Low Air Pressure

- MIL-STD-202, Method 105, Barometric Pressure (Reduced)

- MIL-STD-810, Method 500, Low Pressure (Altitude)

- MIL-STD-883, Method 1001, Barometric Pressure, Reduced (Altitude Operation)

- RTCA/DO-160, Section 4, Temperature and Altitude

Our Equipment Capabilities:

- Altitude range from 15,000 feet below sea level to 100,000 feet

- Altitude combined with hot and cold temperatures

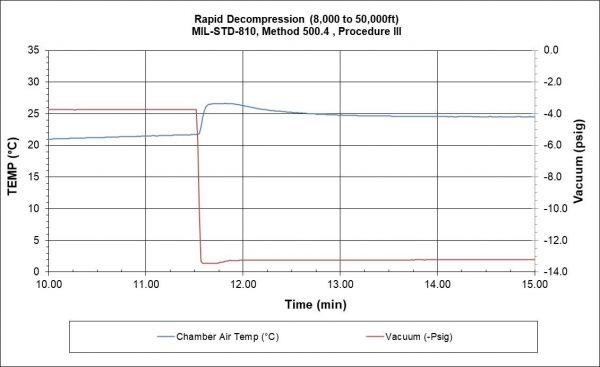

- Rapid decompression in less than 15 seconds

- Sealed access ports to allow products to be operational and monitored during testing

A Rapid Decompression Test Performed at DES According to MIL-STD-810

Related Blogs

If you want to learn more, please read these related blog articles:

- High Altitude Testing: Low Pressure Vacuum Chamber

- Common Altitude Testing Specifications

- Altitude Testing: Low Pressure Vacuum Chamber

Space Simulation Testing

Space simulation or thermal vacuum testing is meant for products that are used in outer space, satellites, missiles, rockets or aircraft. Test altitudes can be over 100 miles high. Space simulation testing uses a specialized Thermal Vacuum Chamber or TVAC. DES’s TVAC can achieve high vacuum levels and apply hot and cold temperatures simultaneously with high vacuums.

DES’s Thermal Vacuum Chamber (TVAC)

Why Perform Space Simulation Testing?

As you can imagine, instrumentation and mission-critical components that are used in satellites or space systems are very expensive and take a long time to go from design to manufacture. Before launch, they must be exposed to space-like temperatures and vacuum levels. It is imperative that they are thoroughly tested not just to survive these extreme conditions, but they must also operate properly and be reliable. Failures can be devastating and extremely costly.

DES can perform quality testing and validation for mission-critical components used in a variety of industries including space, aerospace and aircraft.

Our Space Simulation Equipment Capabilities Are:

- High vacuum levels down to 10-7 torr

- Temperature Range -100°C to +150°C

- Multiple sealed access ports to allow products to be operational and monitored during testing

DES can also simulate the severe vibrations and pyroshocks that occur during a launch.